Proven Deepwater Technology

The Norwegian government has opened more than 281,000 km2 for minerals activities. The vast and brutal area has steeply elevated subsea mountain ridges and seamounts in the deep abyss. Mountain sides with more than 1000 m of elevation difference, steep ridges, and deep trenches are the environment pioneers are moving into to secure minerals and metals for the green transition.

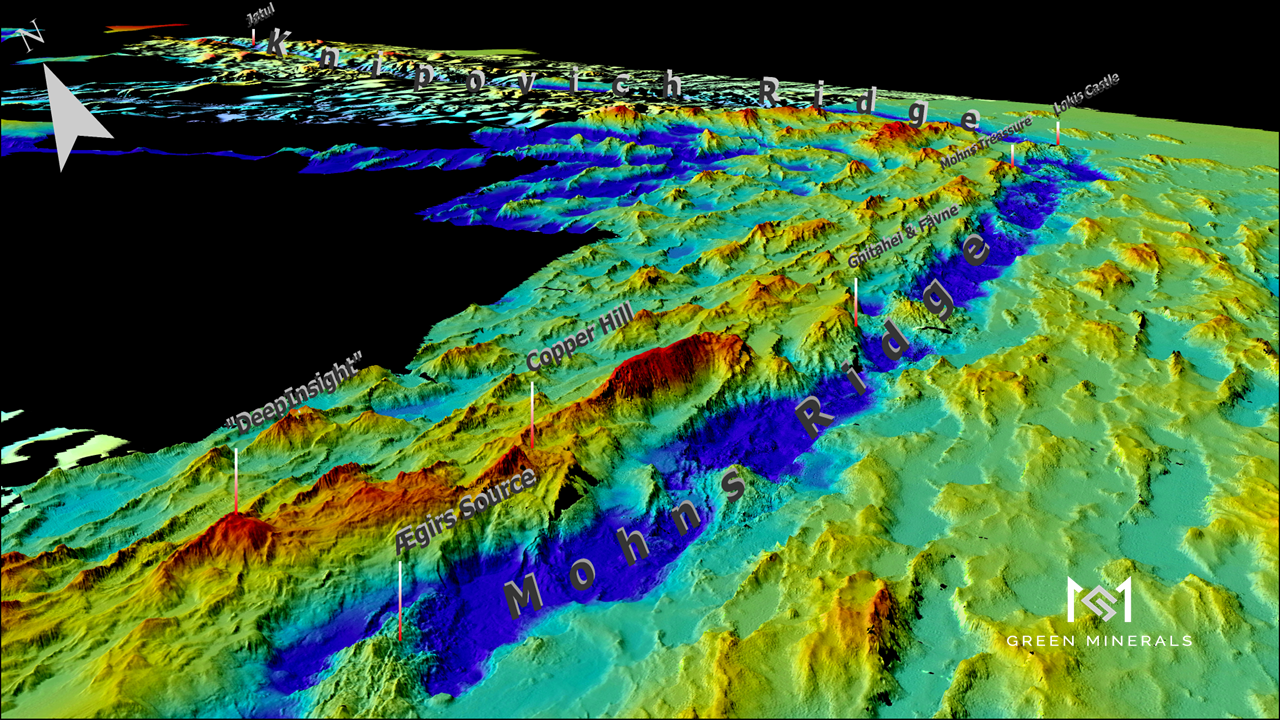

The Seafloor Massive Sulfide deposits are located along the slow to ultra-slow spreading ridges of Mohn and Knipovich. Along the ridges, the University of Bergen and the Norwegian Offshore Directorate have acquired knowledge and valuable data for the last two decades. This has resulted in several discoveries of active, inactive, and extinct hydrothermal vent systems (figure 1). All the data and knowledge acquired by Norwegian authorities and academic institutions will help us identify prospective areas.

Figure 1. Discovered active, inactive and extinct hydrothermal vent systems along the Mohns and Knipovich Ridge.

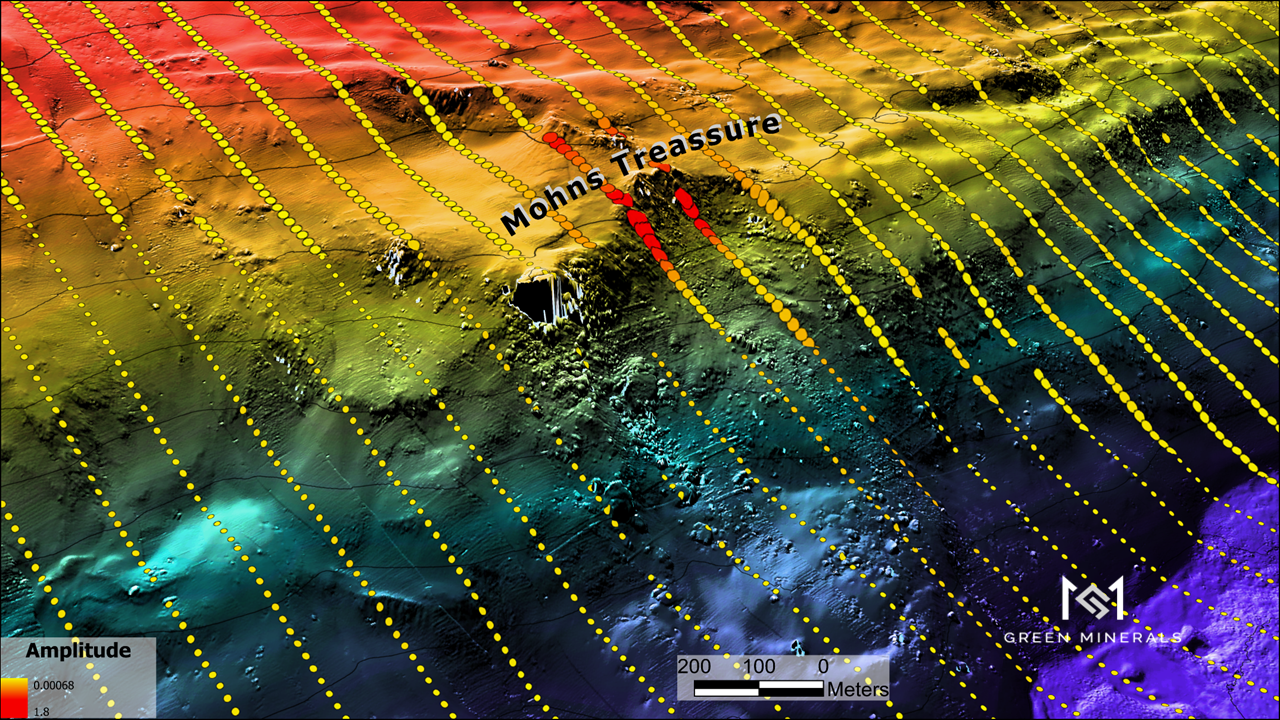

Figure 2. High-resolution bathymetry with Self Potential anomaly over the Mohns Treasure deposit.

A copper-rich sulfide deposit is expected to be the size of a football field. To be able to turn prospects into drillable candidates for mineralization testing a combination of data and techniques are required. High-resolution bathymetry together with synthetic aperture sonar is necessary to understand the surface expression of the deposit and potentially identify extinct vent structures. Electromagnetic data and Self Potential (figure 2) data will be among the used techniques to identify the prospect based on natural conductivity and electromagnetic properties of the sulfides as copper is a very good conductor of electricity. All these techniques and technologies and physical sampling will be a basis for drilling candidates.

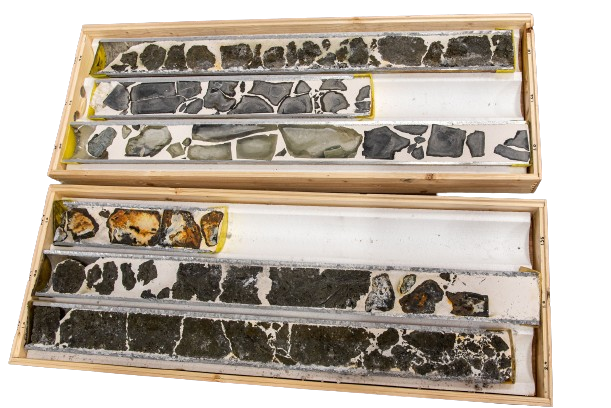

To be able to test the mineralization and understand the grade of the ore, drilling is needed. Several drill cores within the ore body are needed to get control of the grade, and distribution and to be able to model the orebody and its outline. Norwegian Offshore directorate tested coring with coil-tube technology in 2020 (figure 3) and was able to recover approximately 10 m of core.

Figure 3: Slabbed core from the Norwegian Offshore Directorate coring campaign 2020 (Sodir, 2020)

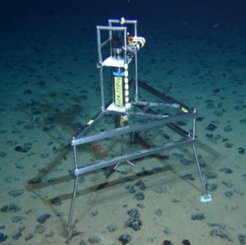

Figure 4. Environmental monitoring sensors (Halboom et al., 2022)

To understand the impact of a mining operation it is vital to understand the environment we are operating in. During exploration campaigns and drilling campaigns environmental monitoring and sampling will be of high priority to increase the understanding of the deep-sea environment. To be granted a production permit an environmental impact assessment must be conducted for the specific project area. In the Pacific Ocean in the Clarion Clipperton Zone (CCZ) environmental data acquisition and understanding has increased rapidly in the last decade. In Norwegian waters, we should acquire the environmental data at an earlier stage to increase our understanding based on the learning made from CCZ (figure 4).

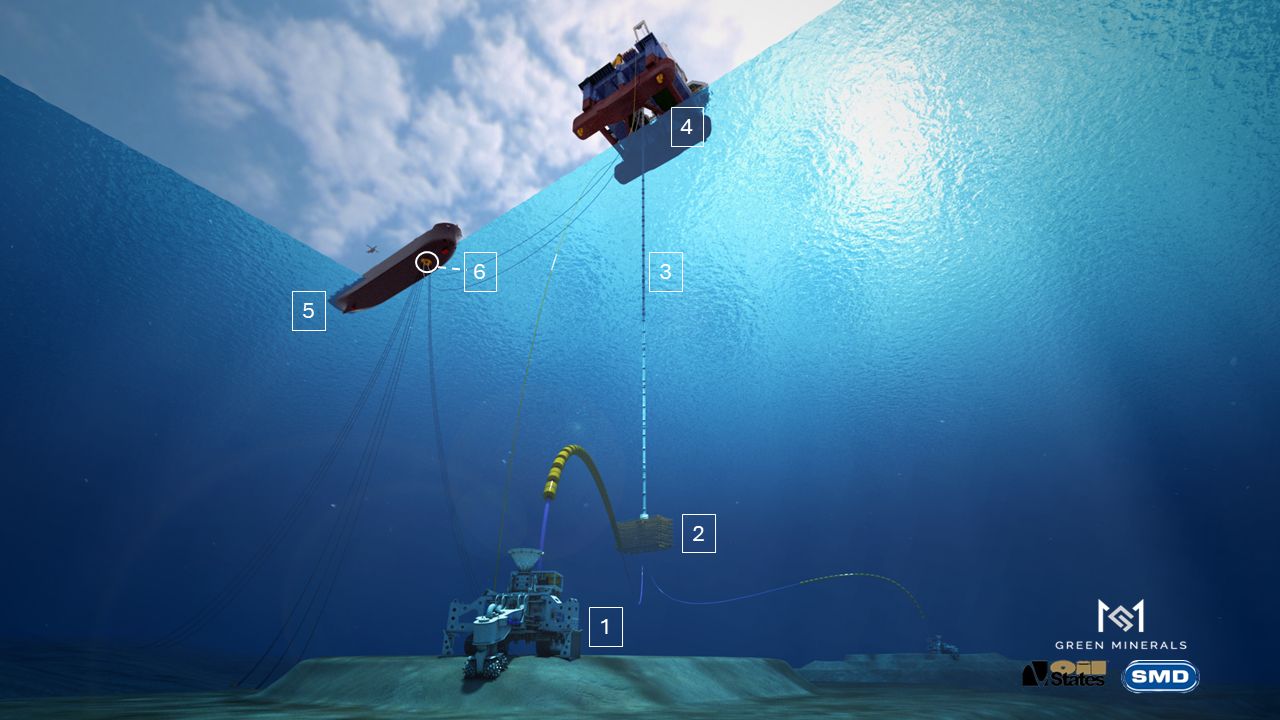

(Select the numbers on the image below to access detailed information on each step of the Production Cycle)

The Production Cycle

Subsea Mining Tool

The first step of the production cycle is to extract ore from the seabed. The Subsea Miner, designed by Soil Machine Dynamics, results from previous designs and the experiences acquired on SMS projects and tested in wet conditions. The cutting heads of the Subsea Mining Tool fragment the ore which is mixed with ambient seawater into a slurry. Counter-rotating cutting heads combined with a central suction point provide a high recovery rate of the fragmented ore and the regular sizing of particles necessary for an efficient slurry convection. Additional shielding can be adapted to the cutting heads to minimise excavation noise and the propagation of fine particles.

Pressure Exchange Chamber

The slurry delivered by the Subsea Mining Tool is vertically transported to the surface through the Riser System. At the bottom of the Riser System, the Pressure Exchange Chamber provides the energy to the slurry to achieve the required flowrate over the +3000m of the riser system. The Pressure Exchange Chamber includes a large degree of redundancy ensuring the high availability of the production system. The Pressure Exchange Chamber is powered by several surface Pressure Displacement Pumps allowing most of the maintenance to be performed at the surface without stopping production. Contrary to Air Lift vertical transportation, the considered setup does not require enlarged riser section for degassing and requires up to 50% less energy at the given production rate. The Pressure Exchange Chamber is designed by a globally recognised equipment supplier for land mining applications where slurries are conveyed over hundreds of kilometres.

Riser System

The Riser System enables the convection of the slurry from the seabed to the surface and the powering of the Pressure Exchange Chamber. The Riser System includes the Oil States Industry's hand-free Merlin Connector which enables the ultra-fast connection of the riser joints constituting the riser system. This system has been already tested on Japanese projects for SMS and equips the most mature nodule collection system for a project in the Pacific Ocean at depth exceeding 4,500m. The reliability and operational speed of the Riser System is a key-enabler for the extreme weather conditions on the Norwegian jurisdiction.

Mining Support Semi-Submersible

At the centre of the Offshore Production System, a revamped Semi-Submersible provides power and control to the subsea equipment. As opposed to a drillship, a semi-submersible provides a very stable platform which tolerates better the harsh conditions of the Norwegian jurisdiction. The Mining Support Semi-Submersible is the hub through which the slurry is conveyed to the Ore Carrier and through which the dewatered seawater is returned to the seabed to power the Pressure Exchange Chamber.

Ore Carrier

As opposed to other concepts, Green Minerals' mining operation transfer the dewatering of the slurry to the ore carrier thus removing one vital function from the mining asset and elegantly addressing the issue of offloading ore in challenging sea conditions using e.g. conveyor belts. The Ore Carrier is equipped with a helideck thus allowing for the helicopter transfer of personnel and spare parts over a very short distance. When entering the work site, the Ore Carrier connects to the Disconnectable Turret and is ready for receiving slurry from the Mining Support Semi-Submersible. When the Ore Carrier reaches full capacity, slurry transfer is stopped, the Disconnectable Turret is lowered to its storage space ready for a new Ore Carrier to take over.

Disconnectable Turret

Green Minerals' concept is an example of technology transfer from the offshore Oil&Gas industry to the new marine minerals industry. The Disconnectable Turret is a technology primary developed for FPSO solutions in the Arctic. It enables the fast connection and disconnection from the Ore Carrier to the Mining Support Semi-Submersible. When connected, the Ore Carrier is effectively moored which reduces the energy consumption for position keeping and offers maximum stability of the Ore Carrier for helicopter operations.

Figure 5. The production cycle.